Then the Arduino running Grbl software converts that g-code to motions on your machine.

The g-code sender sends that g-code to the Arduino and acts as the human-machine interface (HMI). To review, Fusion 360 generates the g-code from the model you want to cut. Fusion 360 generates the g-code, which you can then load into the g-code sender. The g-code sender also serves as the human machine interface (HMI) and runs on a laptop, computer, or Raspberry Pi. The Arduino receives these instructions line by line via USB from a g-code sender. G-code is the instructions that tell the machine what to do. It runs on an Arduino or similar development board.

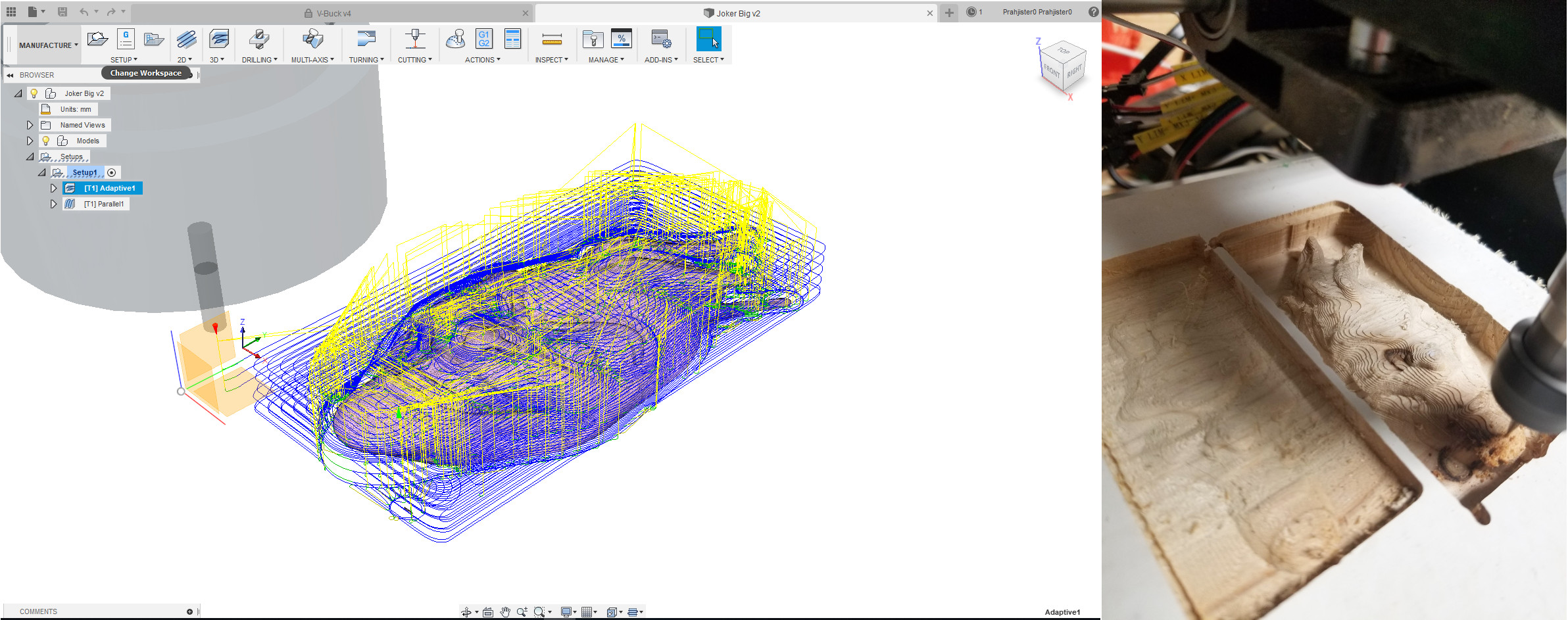

Grbl is software that converts g-code to motions on a CNC machine. What is it exactly? How is it pronounced? And most importantly, where do I find the post? Fusion 360 to Grbl If you have spent much time with desktop CNC machines, you have probably run across the term Grbl. In this post, we are going to explain how to get Fusion 360 running with a Grbl post-processor.

0 kommentar(er)

0 kommentar(er)